In the fast-paced global economy, metal suppliers play a crucial role by ensuring that a wide range of industries have access to the essential materials they need. From construction to electronics, metals form the backbone of contemporary manufacturing processes. The ability of suppliers to thrive and sustain their operations hinges on a combination of strategic sourcing, efficient operations, and adaptive business models that respond to industry demands.

Building Strong Supply Chains for Reliable Metal Sourcing

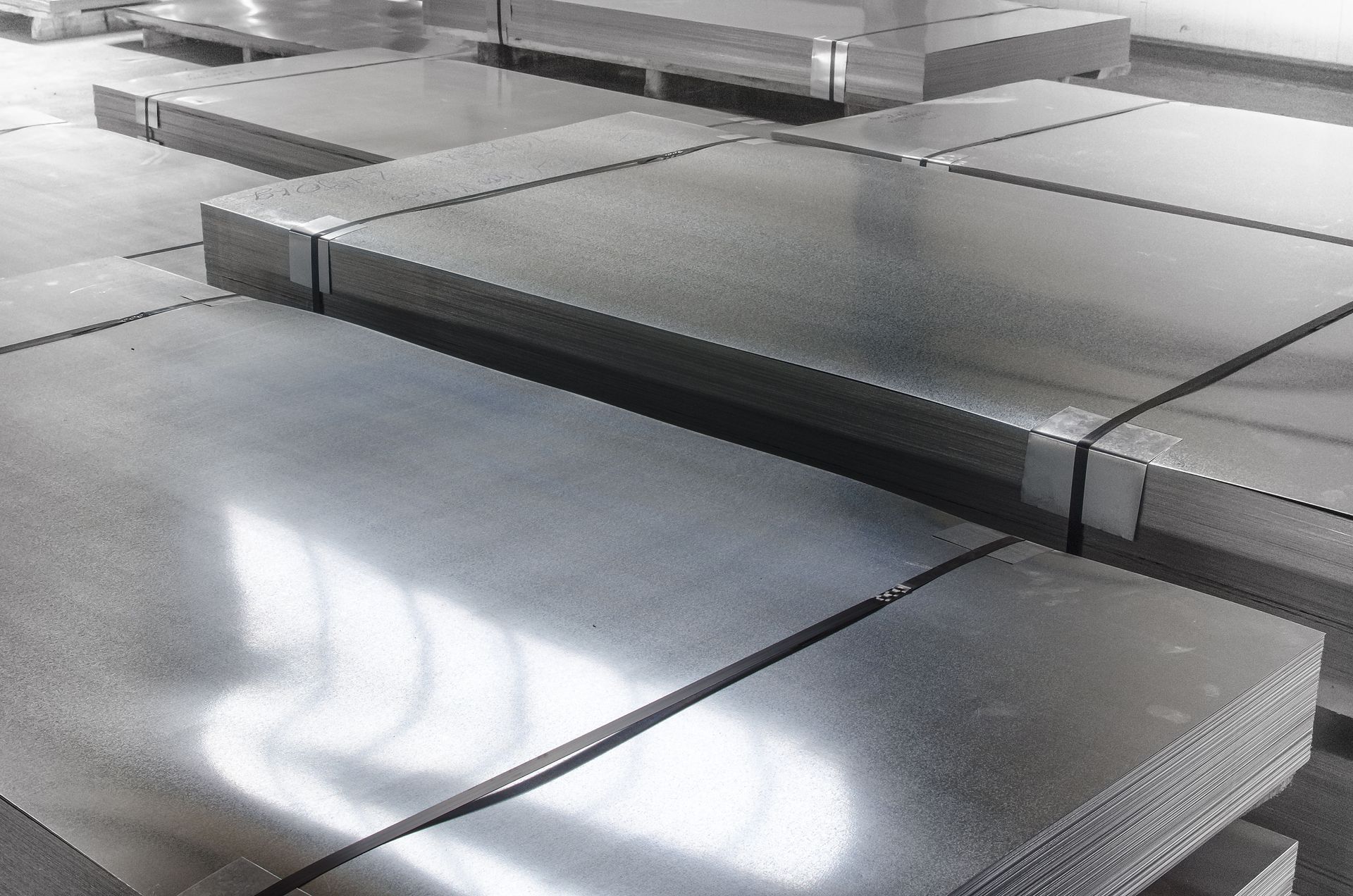

Metal suppliers must first and foremost establish strong supply chains to ensure consistent access to raw materials, as this forms the backbone of their operations. According to WeForum.org, elements like oxygen, silicon, iron, and aluminum are not only abundant in the Earth’s crust but also fundamental to the supply chain of these businesses, as iron and aluminum are widely used metals. By leveraging global and regional partnerships, suppliers secure these raw materials in bulk, which in turn enables them to offer competitive prices and maintain inventory levels that satisfy client demands.

Enhancing Operational Efficiency Through Technology and Logistics

Operational efficiency is another cornerstone of staying afloat in this highly competitive sector. Suppliers invest in cutting-edge technology and skilled labor to optimize their processing techniques. Modern logistics frameworks ensure the timely delivery of metals, while advanced warehousing solutions safeguard materials until they reach the customer. By consistently improving these facets, suppliers can reduce waste and maximize profit margins while enhancing customer satisfaction.

Adapting to Market Changes and Sustainability Demands

In addition to logistics and supply chain management, a forward-thinking approach is crucial for staying relevant. As industries evolve, the demand for metals can shift, requiring suppliers to adapt by expanding their product lines and embracing innovation. Environmental regulations and sustainability trends also prompt suppliers to reduce their carbon footprint by adopting eco-friendly practices and exploring recycled materials. This adaptability not only aligns with global sustainability goals but also positions suppliers as leaders within environmentally conscious markets.

By focusing on these key areas, they not only maintain their competitiveness but also build a resilient business model that thrives in the face of challenges. As technology and industry needs continue to evolve, metal suppliers will undoubtedly play an integral role in shaping the future of manufacturing. Contact SouthCo Metals to learn more today!

Share On: